How a Wire Rope is made: Wires, Strands and Core

The basic elements which make a steel wire rope up are the steel wires, the strands and the core. The single wires wound in helical-shape around a central insert compose the strand. The strands in turn, wound around the core insert (fiber or steel wires’ core), compose the wire rope. The wire ropes may diversify for:

- Diameter

- Wires tensile strength grade

- Wires and Strands direction

- Wires finishing (bright, galvanized or Stainless steel)

- Core type

Any modify on the elementary parameters determinates a different purpose of the wire ropes. Today we’re going to analyze the wires and strands direction: the steel wire ropes lay.

The Steel Wire Ropes Lay: Ordinary or Lang’s

The steel wire rope lay (meant as type and way) is defined by the lay direction of the wires in the strands and as well of the strands in the wire rope. Generally, in the technical data, you can find lays’ indication with the letters “S” and “Z”, written on different sizes. The first letter identify the wires’ lay direction in the strand. The second one refers to the strands’ lay direction in the wire rope. We can speak about:

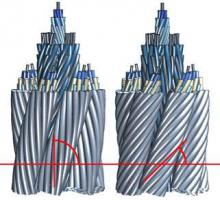

- Ordinary Lay (called Regular Lay too) -> sZ = Right Hand Ordinary Lay (RHOL) or zS = Left Hand Ordinary Lay (LHOL)

This is the most popular lay type. In this case the wires’ lay in the strand is opposite to the strands’ lay in the wire rope. When the strands are wound in a clockwise spiral, the wire rope is defined as Right Hand Ordinary Lay; in the opposite case when the Strands are wound in a counter-clockwise spiral the wire rope is named Left Hand Ordinary Lay. - Lang’s Lay -> zZ = Right Hand Lang’s Lay (RHLL) sS = Left hand Lang’s Lay (LHLL)

In the Lang’s Lay type, the wires and the strands have the same lay direction. Generally with a capital letter “Z” the lay is RIGHT while with the capital letter “S” the lay is LEFT.

X-rays of a Steel Wire Rope: Wires and Strands Lay

Ordinary Lay vs Lang’s Lay

Both solutions have some advantages.

For the steel wire ropes with Ordinary Lay the advantages are:

- A better structural stability;

- Higher number of visible broken wires to reach the Discard criteria according to ISO 4309;

- Easier recognition of the wear/broken wires.

While for the steel wire ropes with Lang’s Lay the advantages are

- A better lean against the shave’s groove and a better running condition as well;

- A better wear resistance;

- Higher lifetime in case of permanent high loads;

- A better behavior when wound on a multi-layer drum.

For a thorough examination of Ropes please visit the Steel Wire Ropes section