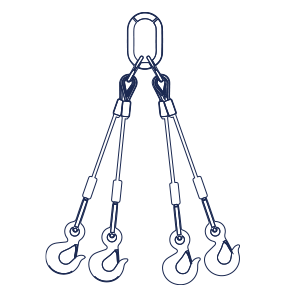

The steel wire rope sling is a very safe and versatile lifting product, you may use it to lift, to tension and to secure a load.

Thanks to a vast offer of end terminations available in the market, the steel wire rope slings are for sure the most commonly used device to lift a load worldwide.

As said before, It is possible to assembly a sling with several kind of terminations such as: soft standard reversed eyes, flemish eyes with steel ferrules, thimbles, swage sockets, spelter sockets, hand spliced eyes, threaded terminals and so on.

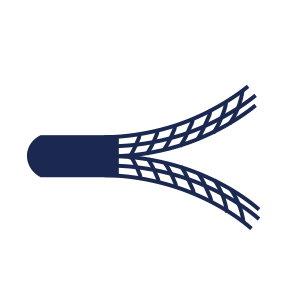

A product that needs particular attention is the cable laid steel wire rope grommet. This is a lifting item in which the technical skills and the experience of the sling makers are fundamental to manufacture a correct product that must be a mix of stability under load, flexibility and safety.

SIRTEF hand makes its grommets in house as all the other kind of steel wire rope slings in order to keep under control the quality of the complete working process.

The cable laid grommet is usually required for heavy lift applications quite common in the offshore industry and in the shipyards, where SIRTEF is well known for the high level of expertise and competence of its personnel and for the constant quality of its products.

All the capacities and technical specifications are in accordance with the existing International Standards EN 13414—1/3 and EN 13411 from 1 to 8 latest editions.

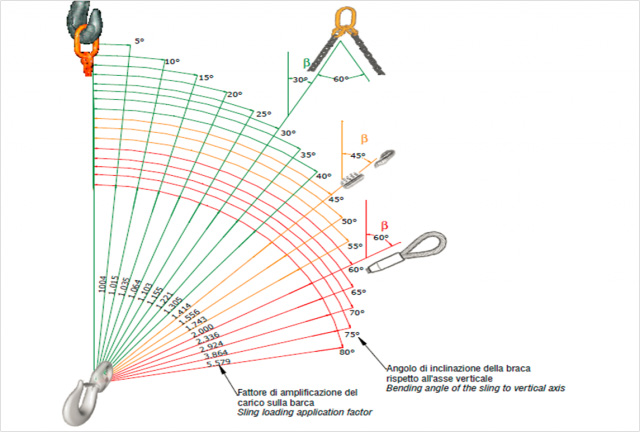

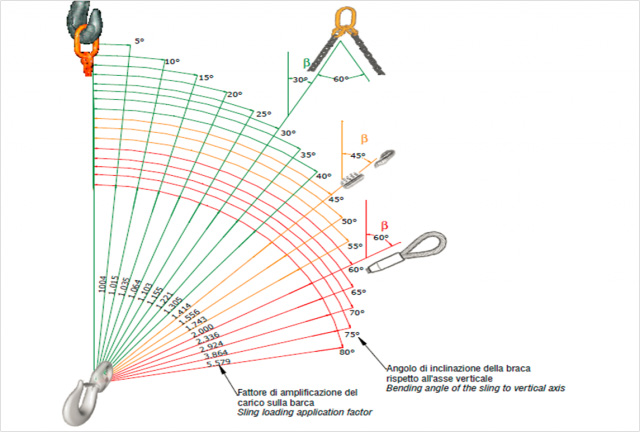

The lifting capacity of a sling, no matter if in steel wire rope or in synthetic fiber webbing /rope, may varies depending on the opening angle respect to the vertical axis (in accordance with EN 13414-2).

The chart here below shows the criteria to follow to determine the sling capacity depending on the opening angle:

Almost any time a rope is used to manufacture a sling with end terminations, the original minimum breaking load of the rope component is reduced by a percentage that depends on the kid of terminals used in the manufacturing.

Here below we introduce some of the most common combination with the corresponding efficiency rate:

-

Reversed mechanically spliced eyes with aluminum ferrules : 90%

-

Flemish eyes with steel ferrules : 90%

-

Swage sockets and threaded terminals : 90%

-

Hand spliced eyes : 80%

-

Clips and wedge sockets : 80%

-

Spelter sockets : 100%

Almost any time a rope is used to manufacture a sling with end terminations, the original minimum breaking load of the rope component is reduced by a percentage that depends on the kid of terminals used in the manufacturing.

Here below we introduce some of the most common combination with the corresponding efficiency rate:

-

Reversed mechanically spliced eyes with aluminum ferrules : 90%

-

Flemish eyes with steel ferrules : 90%

-

Swage sockets and threaded terminals : 90%

-

Hand spliced eyes : 80%

-

Clips and wedge sockets : 80%

-

Spelter sockets : 100%

Almost any time a rope is used to manufacture a sling with end terminations, the original minimum breaking load of the rope component is reduced by a percentage that depends on the kid of terminals used in the manufacturing.

Here below we introduce some of the most common combination with the corresponding efficiency rate: